Technology

Refinery Gas -

Off Gas Recovery

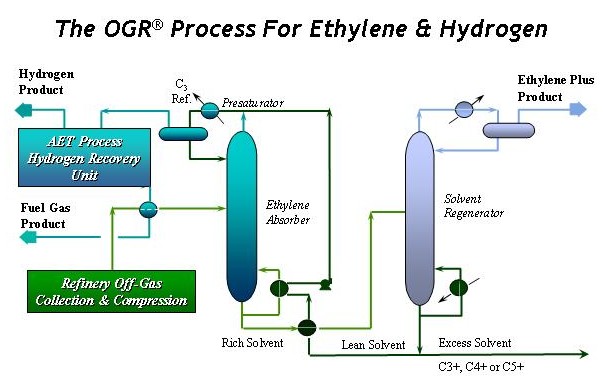

The patented Off-Gas Recovery (OGR)

Process uses conventional unit operations for non-cryogenically absorbing

ethylene and heavier hydrocarbons from FCCU and delayed coker off-gases

that are usually burned in refineries. After treating, the gases

are counter-currently contacted with chilled, pre-saturated lean solvent

in an ethylene absorber which is reboiled at the bottom. The

demethanized rich solvent is fractionated in the solvent regenerator to

produce an overhead ethylene plus product and a bottoms lean solvent

stream for returning to the top of the ethylene absorber. The

solvent is simply the heavier components of the feed gas.

Click here for larger view of drawing.

The ethylene plus product may be

further fractionated to produce ethylene, ethane and propylene plus

products as desired for specific applications. If only C2 product

recovery is required, the solvent regenerator can produce a mixed C2

overhead stream and a C3+ bottoms solvent stream, increasing process

efficiency and reducing fractionation requirements. When desired,

the contained hydrogen in the overhead stream from the ethylene absorber

may be recovered in an AET Hydrogen Recovery unit. For most

applications there are no solvent make-up requirements. Recovery of

C3 plus components from refinery off gases or fuel systems uses the same

technology as LPG recovery from natural gas or ethylene recovery from

refinery gases. The performance difference is in the feed gas.

FCCU off-gas is typically more suitable for recovery of the high value

ethylene/ethane mix. Coker off-gas will see higher profitability

from C3 plus recovery. Compared to natural gas, the coker or fuel

gas systems are much richer in C3 plus, increasing profitability and

giving absorption technology a decided edge versus use of cryogenic

technologies. In C3 plus operation, the AET technology would

operate with a C5+ regenerator tower bottoms product (and solvent

composition) and a C3-C4 regenerator overhead product.

ADVANCED

EXTRACTION

TECHNOLOGIES,

INC.

![]()